The Future of IC Engine Design

The future of IC engine design

Five Trends for 2021.

The invention of the internal combustion (IC) engine was a boon to transportation and efficiency and all things America. But, as IC technology ages and environmental concerns increase, alternatives are looking to take its place.

Automakers and consumers alike are mulling the future of internal combustion engine production, and looking at what will replace the internal combustion engine -- or what parts powder metallurgy (PM) got involved in.

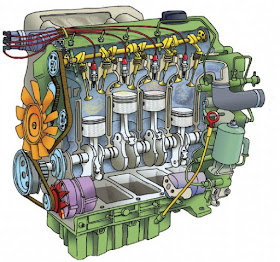

Think about where the PM has been used in an engine. Advances include self-lubricating valve guides, connecting rods, variable valve timing, and so on.

Looking at the background of what got us here, as well as new efficiency and environmental challenges that powder metal could help solve, is a lesson no OEM engineer should miss.

1. Restrictions on CO2 Emissions

The Global Carbon Project reported that worldwide carbon emissions reached an all-time high in 2018, with the number expected to increase again in 2019.

The EPA published Greenhouse Gas Emission guidelines for passenger cars and trucks, with Phase 2 affecting model years through 2025. Although the EPA seems to be rethinking some guidelines, it’s still the political and environmental atmosphere that’s pushing internal combustion engine efficiency improvements through, more so than consumer demand.

Whether engineers and executives personally agree or not with the changes in the air, the industry is moving steadily in that direction.

2. How to Increase Efficiency of IC Engine Emissions?

The Office of Energy Efficiency & Renewable Energy reports that manufacturers reduced pollutant emissions by more than 99% over the last 30 years. Creative minds accomplished this while still maintaining or increasing fuel economy.

In addition to gasoline and diesel, manufacturers are studying other ways to increase fuel economy:

- Using biodiesel

- Using other alternative or renewable fuels

- Combining IC engines with hybrid electric powertrains

3. Diesel Engines Vs. Traditional Gasoline Engines

When Europeans switched from diesel to gasoline cars, there was a related increase in carbon dioxide emissions. In an unexpected twist, some of today’s auto strategies are based around diesel engines.

Many big diesel trucks actually create less CO2 emission than some smaller, gas-powered vehicles, reports indicate. Increased technology has produced diesel-powered engines that can fuel smaller vehicles and provide:

- Better gas mileage

- Lower carbon emission rates

- Greater torque

- A longer-lasting engine

4. Competing With Electric Engines

You knew this was coming. Although gasoline powered engines don’t appear to be completely disappearing, they do face stiff competition from their electric rivals.

While some see electric cars as the future, even BMW isn’t backing away from the internal combustion engine just yet.

One thing IC engine supports could hang over the heads of the pro-electric crowd was their battery. Specifically, its:

- Size

- Cost

- Longevity

- Charging capabilities, or lack thereof

However, electric car prices are projected to be competitive as soon as 2022 as battery costs plummet. The battery was once about 50% of the car’s cost, but could go as low as 20% by 2025. These reductions are certainly coming more quickly than the market expected.

Concerns about range are less of an issue for electric vehicles going forward. The technology is evolving, and more charging stations are popping up. “Range anxiety” (consumer fear that they’ll be stranded with nowhere to charge their battery) is still a very real issue OEMs still need to resolve.

5. Powder Metallurgy Supports the Move to Eco-Friendly

Powder metallurgy is becoming more of a factor in component design for engines, whether IC engine designers like it or not.

The “green” technology that is powder metallurgy goes hand in hand with the future of the eco-friendly automobile. Sintered soft magnetic materials with higher densities are providing a boost in performance not seen before. You may have heard the story of powder metal before, but these new materials are different from the Standard 35 materials that manufacturers have relied on for decades.

MPIF’s Standard 35 is a great baseline for powder metallurgy manufacturers, but your future designs may need materials and processes that surpass “standard” performance levels. In some cases you can even eliminate a component from the assembly by designing with powder metal.

Today’s advanced compaction technology may be a little more expensive at the onset, but it can save manufacturers (and drivers) a lot in the long run.

Many components can be transitioned to powder metal. Powder metallurgy has made great advances in creating small parts for electric motors and other auto parts for many reasons:

- Reduces weight

- Improves electric motor efficiency, including better magnetic properties

- Creates net-shape parts

- Allows for advanced materials and processes

- Higher strength and hardness

Specifically, soft magnetic composite materials are leading the way to a super-efficient electric motor.

Powder metallurgy is not just rods and end caps any longer!

Where Will You Turn Next?

Today’s powder metallurgy services allow for a smooth transition from the traditional internal combustion engine design to the more efficient and environmentally conscious engines of the future. Advances in PM materials (like you'll find below) and processes (like sintering) have made that possible.

Of course, internal engines will still be around for a long time. Powder metal can still bring significant benefits to IC engines too.

Comments

Post a Comment